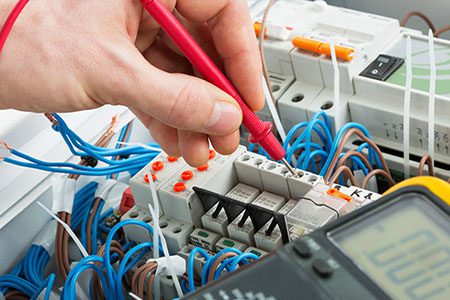

Production of switchboards and electrical installation

We have been producing Low-voltage switchboards for over 30 years. During that time, we have gained irreplaceable experience, thanks to which we can build the right switchboard for you as well.

We manufacture switchboards of any type and purpose up to 1 000 V and 4 000 A. Most often, these are switchboards for power engineering, switchboards for automation and switchboards for data systems. In our portfolio, however, you will also find distribution and compensating switchboards or specialized switchboards for cranes and manipulation technology. We also construct switchboards for civic amenities, residential and individual construction.

We build RACK switchboards or integrate them into machines and production lines.

Certification according to ČSN EN ISO 9001:2009 in accordance with the new set of standards ČSN EN 61439 is proof of the real expertise of our production.

We have almost 1 000 m2 of production and warehouse space, in which we produce more than 80 switchboard arrays per month.

In addition to the construction of switchboards, we also carry out assembly and commissioning, or revision and service activities.

We have satisfied customers here and around the world, and you can also contact us with confidence.

How is the production of the switchboard carried out?

Based on the project documentation created by us or supplied by the client, we will design the construction solution of the switchboard according to the valid standards and regulations with the help of CAD/Eplan software.

After mutual agreement of the input parameters, we move on to the production itself. This takes place in our own production facilities, where everything is subject to the relevant standards. In case you need a FAT or inspection at the production site, this is not a problem. For this situation, our production is equipped with a Wi-Fi network for direct communication between the client and its parent server. We are easily accessible by transport and would be happy to welcome you here.

We have experience in switchboard logistics all over the world. We can prepare them to handle travel on land, on water and in the air. We prioritize the customer’s requirements, but we can also provide safe packaging for transport on our own.

In addition to the production of switchboards, we also offer all electrical installation work on equipment up to 1000 V. We carry out subsequent certified inspections resulting in legally binding certificates and revision reports.

We offer warranty and post-warranty service and repair of electrical equipment based on service contracts. We also service switchboards of other manufacturers.

How is the production of the switchboard carried out?

Based on the project documentation created by us or supplied by the client, we will design the construction solution of the switchboard according to the valid standards and regulations with the help of CAD/Eplan software.

After mutual agreement of the input parameters, we move on to the production itself. This takes place in our own production facilities, where everything is subject to the relevant standards. In case you need a FAT or inspection at the production site, this is not a problem. For this situation, our production is equipped with a Wi-Fi network for direct communication between the client and its parent server. We are easily accessible by transport and would be happy to welcome you here.

We have experience in switchboard logistics all over the world. We can prepare them to handle travel on land, on water and in the air. We prioritize the customer’s requirements, but we can also provide safe packaging for transport on our own.

In addition to the production of switchboards, we also offer all electrical installation work on equipment up to 1000 V. We carry out subsequent certified inspections resulting in legally binding certificates and revision reports.

We offer warranty and post-warranty service and repair of electrical equipment based on service contracts. We also service switchboards of other manufacturers.

SWITCHBOARDS FOR POWER ENGINEERING

The power industry is a sector where about 25-30% of our annual production of switchgear is directed. For this (and not only this) type of switchboards we are equipped with hydraulic equipment for cutting, bending and other modification of copper or aluminium bus bars and flexibars up to a cross section of 100*10mm. Combined with the extensive experience of our employees, we can manufacture any distribution switchboard up to a rated current of 3200A.

SWITCHBOARDS FOR INDUSTRIAL AUTOMATION AND TECHNOLOGY

Every machine needs a constant and safe source of electrical energy and a corresponding control system. Our switchboards can be built directly into production lines, robotic workplaces or single-purpose machines. Switchboards for automation and industrial technology are the most typical products of our production. It is the area in which approx. 35-45 % of our production falls. Switchboards for machines and technological equipment, switchboards with control systems and switchboards for M&R have been our domain for a long time.

SWITCHBOARDS FOR DATA SYSTEMS

We have extensive experience in the production of switchboards for IT technology and data collection. We have manufactured and delivered many 19inch assemblies according to our own and client’s designs with rotatable frames and in fixed construction. We have offered clients elegant solutions to their problems with the size and layout of these assemblies, often with innovative and surprising results for the client.

Why choose switchboards from us?

We perform control calculations of heat loss

When designing the structure, we rely on proven patterns

We use digitalisation in the design and production of switchboards

Production of atypical switchboards according to customer requirements, including appearance

suppliers COMPONENTS FOR THE MANUFACTURING OF DISTRIBUTORS

Our products and services

WHY CHOOSE

PROFESSIONALISM AND EXPERIENCE

Every one of our employees is a professional in their field. Our services and products are the result of the experience and expertise we have accumulated for over 30 years. We are not afraid of challenges and always strive to find solutions that meet all of our customers' demanding requirements.

CERTIFICATION

We hold several quality and safety certificates. In addition, we follow a set of strict internal guidelines designed to maximize the quality and efficiency of our work. All these standards are regularly checked by internal and external audits.

COMPREHENSIVE SOLUTION

The ELVAC Group brings together several companies that, thanks to interdisciplinary cooperation, are able to provide comprehensive solutions for a wide range of industrial applications. We provide services and products that intertwine and complement each other, ultimately making your project easier and saving you costs.