INDUSTRIAL AUTOMATION

Machine vision

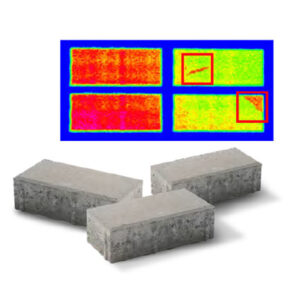

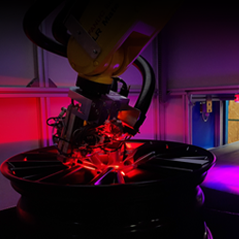

We implement integrations of machine vision systems from camera sensors, through cameras with third-party user environments, to multi-camera systems with our own software solutions and the use of neural networks. We also evaluate data from linear 3D scanners with moving objects as well as planar scanners in static installations. Our applications reliably check product quality, assembly completeness and guide robots.

Our goal is absolute quality control, precise measurements, reliable defect detection and stable evaluation of all required values.

In conjunction with deep learning, camera and optical inspection systems can provide a relevant source of input data for control systems or security and analytical applications.

Our electrical wholesale offers a wide range of sensors for machine vision applications.

We implement integrations of machine vision systems from camera sensors, through cameras with third-party user environments, to multi-camera systems with our own software solutions and the use of neural networks. We also evaluate data from linear 3D scanners with moving objects as well as planar scanners in static installations. Our applications reliably check product quality, assembly completeness and guide robots.

Our goal is absolute quality control, precise measurements, reliable defect detection and stable evaluation of all required values.

In conjunction with deep learning, camera and optical inspection systems can provide a relevant source of input data for control systems or security and analytical applications.

Our electrical wholesale offers a wide range of sensors for machine vision applications.

Do you have any questions or would you like to cooperate with us?

Write to us and we will get back to you.

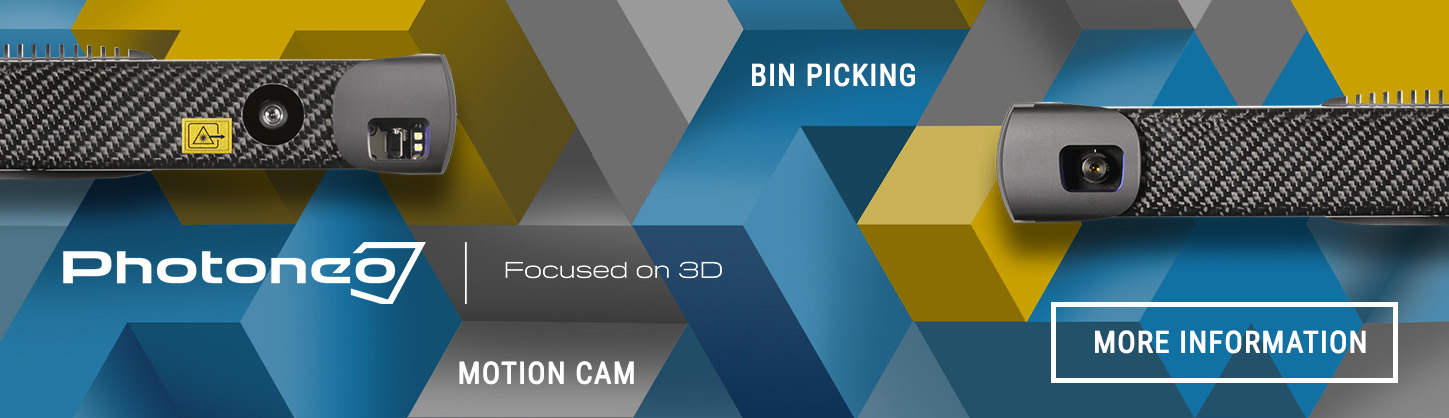

we implement the photoneo solution

We are the official integrator of Photoneo, a Slovak company offering comprehensive 3D scanning solutions for industrial machine vision applications. Thanks to its patented 3D technology, it offers the highest resolution and accuracy camera in the world, which opens up new possibilities in areas such as bin picking, palletizing, warehouse automation, etc.

Most frequent types of realizations

Automatic camera control of production in the automotive industry, engineering, metallurgy, food industry

Camera-based quality control, component identification, product measurement and sorting, or robot guidance

Image analysis from camera systems, camera search

Surface defects detection

Measurement and control of manufacturing tolerances

Key benefits

Automation of control processes

Increased quality and thus production efficiency

Medium-term return on investment

Easy modification and expandability of the systém

- Industrial wiring

- Technique for switchboard construction

- Machinery security system

- Crane and lifting technology

- Sensor technology

- Circuit breakers

WHY CHOOSE

PROFESSIONALISM AND EXPERIENCE

Every one of our employees is a professional in their field. Our services and products are the result of the experience and expertise we have accumulated for over 30 years. We are not afraid of challenges and always strive to find solutions that meet all of our customers' demanding requirements.

Strojové vidění

machine vision

CERTIFICATION

We hold several quality and safety certificates. In addition, we follow a set of strict internal guidelines designed to maximize the quality and efficiency of our work. All these standards are regularly checked by internal and external audits.

COMPREHENSIVE SOLUTION

The ELVAC Group brings together several companies that, thanks to interdisciplinary cooperation, are able to provide comprehensive solutions for a wide range of industrial applications. We provide services and products that intertwine and complement each other, ultimately making your project easier and saving you costs.

Strojové vidění

machine vision strojové vidění